Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

Nickel Foam Electrode: A Comprehensive Guide

Nickel foam electrodes are advanced materials widely used in energy storage and conversion systems, such as batteries, supercapacitors, and fuel cells. They consist of a porous nickel structure that provides a large surface area for electrochemical reactions, making them highly efficient for various applications.

Below is an indepth exploration of nickel foam electrodes, including their composition, properties, manufacturing process, applications, advantages, and limitations.

●1. What Is a Nickel Foam Electrode?

A nickel foam electrode is a threedimensional (3D) porous material made from nickel, characterized by its opencell structure. The foamlike architecture offers high porosity, excellent electrical conductivity, and mechanical stability, making it ideal for use as an electrode in electrochemical devices.

Key Features

High Surface Area: The porous structure maximizes the active surface area for electrochemical reactions.

Excellent Conductivity: Nickel's inherent conductivity ensures efficient electron transfer.

Mechanical Stability: The foam structure is robust and can withstand repeated cycling in energy storage systems.

●2. Composition and Structure

Nickel Foam

Nickel foam is typically produced through processes like sintering, electroplating, or chemical vapor deposition (CVD).

It consists of interconnected nickel strands forming a network of pores with sizes ranging from micrometers to millimeters.

Electrode Coatings

To enhance performance, nickel foam electrodes are often coated with active materials, such as:

Metal Oxides: NiO, MnO₂, Co₃O₄

Conducting Polymers: Polyaniline, polypyrrole

CarbonBased Materials: Graphene, carbon nanotubes

Transition Metal Dichalcogenides (TMDs): MoS₂, WS₂

These coatings improve the electrode's capacity, rate capability, and cycling stability.

●3. Manufacturing Process

The production of nickel foam electrodes involves several steps:

1. Fabrication of Nickel Foam:

Sintering: Nickel powder is compacted and heated to form a porous structure.

Electroplating: Nickel is deposited onto a substrate (e.g., steel mesh) to create a foamlike structure.

Chemical Vapor Deposition (CVD): Nickel is deposited using gasphase reactions.

2. Surface Treatment:

The foam is cleaned and treated to remove impurities and enhance wettability.

3. Coating with Active Materials:

Techniques like electrodeposition, solgel synthesis, or hydrothermal methods are used to deposit active materials on the foam surface.

4. Assembly:

The coated nickel foam is integrated into the desired electrochemical device.

●4. Properties of Nickel Foam Electrodes

| Property | Description |

|||

| High Porosity | Provides a large surface area for electrochemical reactions. |

| Excellent Conductivity | Ensures efficient electron transfer during charge/discharge cycles. |

| Mechanical Stability | Resists deformation and maintains structural integrity under cyclic loading. |

| Corrosion Resistance | Nickel exhibits good resistance to corrosion in alkaline environments. |

| Lightweight | Reduces overall weight in portable energy storage systems. |

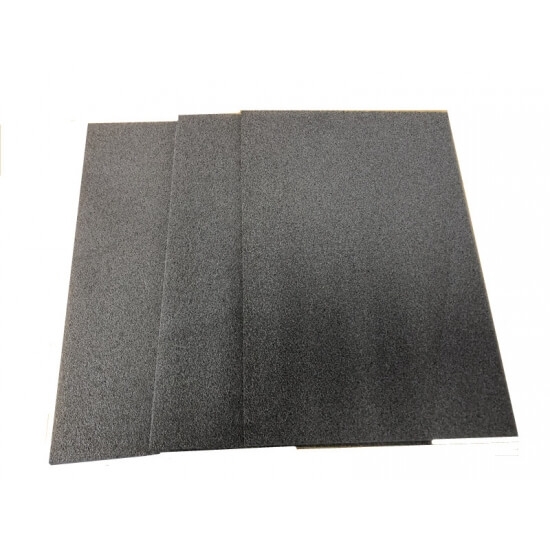

Iron Nickel Alloy foam

●5. Applications of Nickel Foam Electrodes

Energy Storage

Batteries: Used in nickelmetal hydride (NiMH) batteries and lithiumion batteries.

Supercapacitors: Enhances capacitance and power density due to its high surface area.

Energy Conversion

Fuel Cells: Acts as a catalyst support in proton exchange membrane (PEM) fuel cells.

Water Electrolysis: Serves as an electrode for hydrogen production through water splitting.

Environmental Remediation

Wastewater Treatment: Utilized in electrochemical reactors for removing pollutants.

Desalination: Employed in capacitive deionization systems for water purification.

Sensors

Electrochemical Sensors: Used for detecting gases, ions, and biomolecules due to its sensitivity and selectivity.

●6. Advantages of Nickel Foam Electrodes

High Surface Area: Maximizes reaction sites for improved performance.

Excellent Conductivity: Facilitates rapid electron transfer.

CostEffective: Nickel is more affordable than precious metals like platinum or palladium.

Versatile: Suitable for a wide range of applications in energy storage, conversion, and environmental technologies.

Scalable: Can be produced in large quantities for industrial use.

●7. Limitations of Nickel Foam Electrodes

Weight: Although lightweight compared to some materials, nickel foam may still be heavier than carbonbased alternatives.

Corrosion in Acidic Environments: Nickel is less stable in acidic conditions, limiting its use in certain applications.

Lower Energy Density: Compared to other advanced materials (e.g., graphene), nickel foam may have lower theoretical energy storage capacity.

Processing Challenges: Coating active materials uniformly on the porous structure can be technically demanding.

●8. Future Trends and Innovations

1. Hybrid Materials:

Combining nickel foam with other materials (e.g., graphene, carbon nanotubes) to enhance performance and overcome limitations.

2. Advanced Coatings:

Developing new coating techniques to improve stability, conductivity, and catalytic activity.

3. Sustainability:

Exploring environmentally friendly methods for producing nickel foam and reducing waste.

4. Novel Applications:

Expanding the use of nickel foam electrodes in emerging fields like wearable electronics, flexible devices, and renewable energy systems.

●9. Pricing of Nickel Foam Electrodes

The cost of nickel foam electrodes varies based on factors such as size, thickness, porosity, and coating type. Below are approximate price ranges:

Raw Nickel Foam: $5–$20 per square meter.

Coated Nickel Foam Electrodes: $20–$100 per square meter, depending on the active material and application.

Factors influencing price include:

Material Quality: Higher purity nickel and advanced coatings increase cost.

Manufacturing Process: Complex fabrication techniques raise prices.

Supplier: Prices vary between manufacturers and distributors.

●Conclusion

Nickel foam electrodes are versatile and highperformance materials with significant potential in energy storage, conversion, and environmental applications. Their unique combination of high surface area, excellent conductivity, and mechanical stability makes them indispensable in modern electrochemical systems.

If you're considering using nickel foam electrodes for your project, understanding their properties, manufacturing process, and potential applications will help you make informed decisions. Let me know if you'd like further details or guidance!

+86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588